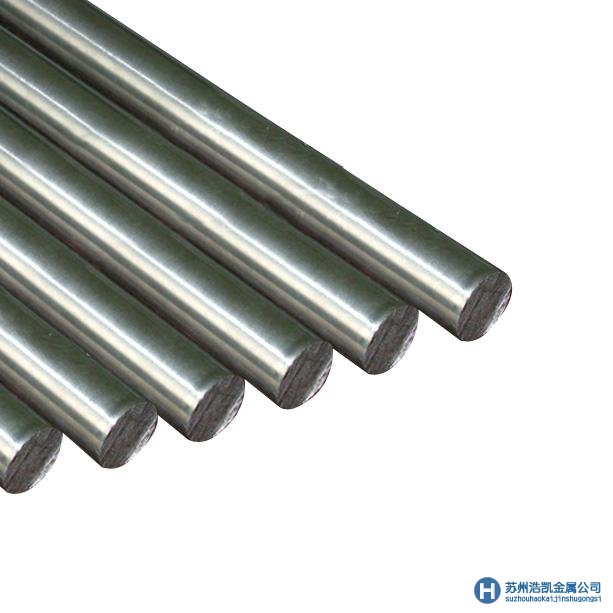

H11 steel

Grade: 4Cr5MoVSi/ SKD6/ H11/ X38CrMoV51/ 1.2343

Chemical composition of H11:

|

C |

Si |

Mn |

Cr |

Mo |

V |

P |

S |

|

0.33-0.43 |

0.80-1.20 |

0.20-0.50 |

4.75-5.50 |

1.10-1.60 |

0.30-0.60 |

≤0.030 |

≤0.030 |

Specification :

|

Round bar |

Diameter (mm) |

Length (mm) |

|

|

50~500 |

2000~5800 |

|

|

|

plate/sheet |

Thickness (mm) |

Width (mm) |

Length (mm) |

|

20~400 |

80~1000 |

2000~5800 |

Characteristic:

1. H11: Excellent hot strenght and hardness.

2, Excellent toughness in medium temperature condition.

3, Heat treatment deformation of H11 is small.

Heat treatment:

1,Anneal hardness: ≤HB235

2,Hardening temperature: 1020-1050

3,HRC Secondary hardness: 54

4Cr5MoSiV steel,SKD6 steel,H11 steel,1.2343 steel

Application:

H11 is used for making cast moulds for aluminum and zinc alloy,extrusion moulds,hot-forging moulds,and plastic

moulds of high output.