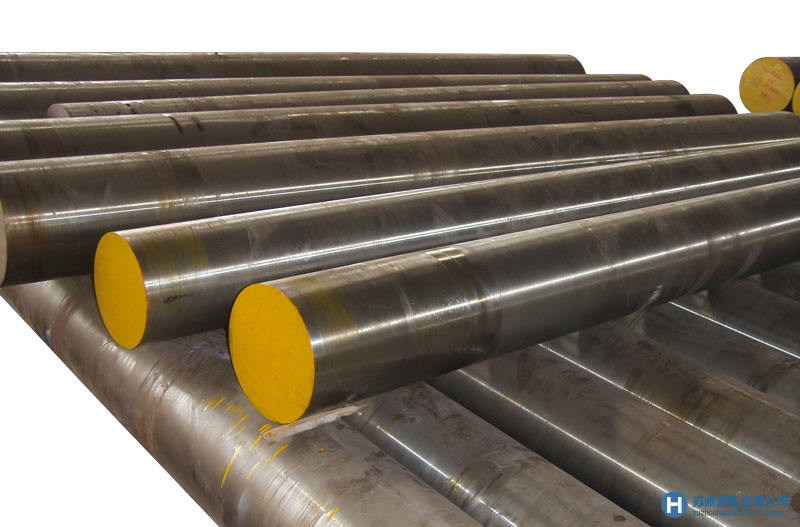

Cr12MoV tool steel

Grade: Cr12MoV/SKD11/1.2601/DC11

Chemical composition:

|

Standard |

Grade |

C |

Si |

Mn |

Cr |

Mo |

V |

P |

S |

Other |

|

GB |

Cr12MoV |

1.45-1.70 |

≤0.40 |

≤0.40 |

11.0-12.5 |

0.40-0.60 |

0.15-0.30 |

≤0.030 |

≤0.030 |

Cu≤0.30 |

|

AISI |

X12m |

1.40-1.60 |

0.30-0.50 |

0.30-0.50 |

11.0-13.0 |

0.70-1.20 |

(0.80) |

≤0.025 |

≤0.025 |

Co:0.60 |

|

JIS |

SKD11 |

1.40-1.60 |

0.40 |

0.50 |

11.0-13.0 |

0.80-1.20 |

0.20-0.35 |

≤0.025 |

≤0.01 |

--------- |

|

DIN |

1.2601 |

1.45-1.70 |

≤0.40 |

≤0.40 |

11.0-12.5 |

0.40-0.60 |

0.15-0.30 |

≤0.030 |

≤0.030 |

Cu≤0.30 |

Specification :

|

Round bar |

Diameter (mm) |

Length (mm) |

|

|

50~500 |

2000~5800 |

|

|

|

Plate/sheet |

Thickness (mm) |

Width (mm) |

Length (mm) |

|

20~400 |

80~1000 |

2000~5800 |

Cr12MoV Steel,SKD11 Steel,1.2601 Steel

Features :

1) low deformation when quenching

2) good hardenability and abrasion resistance

3) good hardness and ductility

Applications :

For making all sorts of cold working die steels, cutting tools and measuring tools, such as cold extruding dies, thread rolling flat dies, gauge, etc.

|

annealing |

500-600°C , air cooling or furnace cooling, HB:207-255 |

|

Hot treatment quench |

950-1000°C air cooling HRC:58-62 |

|

|

1020-1040°C air cooling HRC: 62-63 |

|

|

1115-1130°C air cooling HRC: 42-50 |

|

backfire |

150-170°C 200-275 °C 400-425 °C 510-520°C |

|

HRC |

61-63 57-59 55-57 60-61 |